EPS Foam Packaging & XPS Extruded Boards — Made in Cambodia

We manufacture and deliver foam products locally: reliable quality, flexible sizes, and on‑time service for your business.

-

✓Custom cutting, CNC contouring, and protective edge profiles.

-

✓Strict quality control, reliable density and compression strength.

-

✓We provide production and delivery services only.

About Wanfang

We are a local Cambodian manufacturer specializing in EPS foam packaging and XPS extruded boards. Our automatic cutting and extrusion lines ensure stable quality and quick turnaround.

Our company specializes in producing high-quality, high-density XPS extruded boards with exceptional thermal insulation properties, superior compressive strength, moisture resistance, and durability. Our products are widely used in building insulation applications including walls, roofs, and floors, particularly suitable for cold storage, basements, and exterior wall insulation systems. Additionally, XPS boards are extensively applied in infrastructure projects such as highways, canals, and airport runways as roadbed isolation layers, effectively preventing frost heave damage and extending road service life. We also provide various foam boards, foam boxes, and foam packaging products that are lightweight with excellent cushioning properties and outstanding moisture resistance. These products are widely used in electronics, home appliances, food thermal boxes, medical equipment, and other fields, providing reliable protection during transportation and storage. Meanwhile, our dry mortar product series covers XPS board-specific adhesive mortar, crack-resistant mortar, tile adhesive, self-leveling cement, high-strength non-shrink grouting material, road repair mortar, and other application scenarios to meet various construction needs. With years of industry experience and technical expertise, we are committed to providing customers with environmentally friendly, durable, and high-quality comprehensive building material solutions. Choose Wanfang, choose quality and reliability assurance.

Quality Manufacturing

Automatic cutting, consistent density, and careful inspection deliver durable, high‑performance foam products.

- ✓Density & dimension control

- ✓Compression strength tests

- ✓Clean cuts & neat edges

Flexible Orders

Custom sizes, density selections, and small‑to‑bulk orders. We deliver on time across Cambodia.

- ✓Cut‑to‑size EPS & XPS

- ✓Protective packaging shapes

- ✓Delivery services only

Trusted Partner

Clear quotations, stable supply, and responsive support to keep your production running smoothly.

- ✓Fast quotation

- ✓Consistent lead time

- ✓After‑sales support

Products

Two main product lines to cover packaging and insulation needs.

EPS (Expanded Polystyrene)

Lightweight, shock‑absorbing foam for protective packaging, fruit & seafood boxes, appliance buffers, and custom inserts.

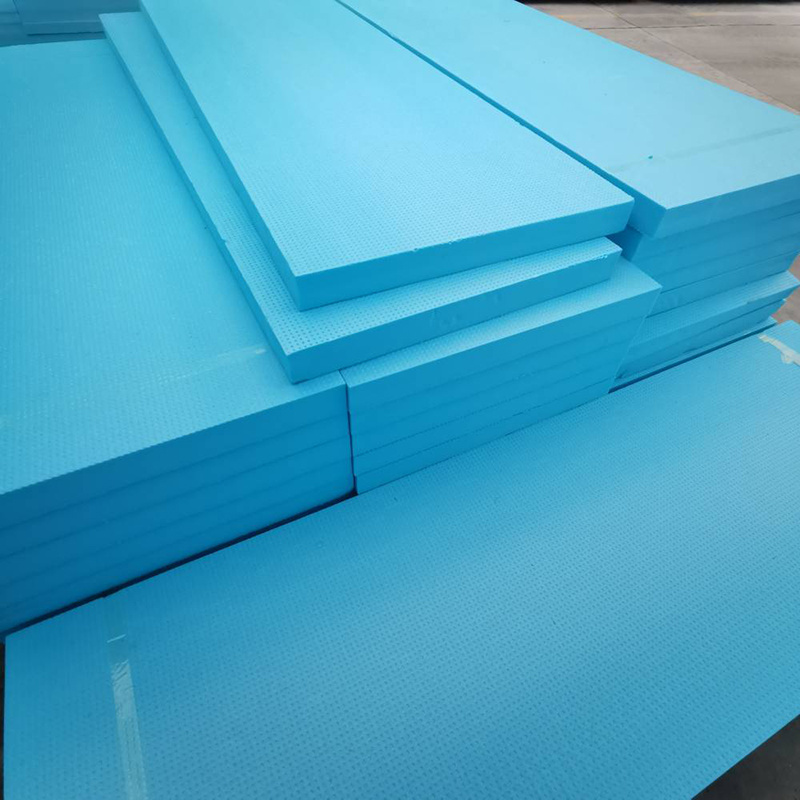

XPS (Extruded Polystyrene)

Closed‑cell insulation boards with high compressive strength for floors, roofs, and cold‑chain applications.

Dry Powder Mortar

Professional construction mortars including XPS adhesive, crack-resistant mortar, tile adhesive, self-leveling cement, and road repair solutions.

Custom Packaging Shapes

Send drawings or samples. We can develop molds or cut profiles to fit your products precisely.

Industries we serve

Quick Estimator

Estimate EPS weight & price from size, density, and price per kilogram. (For reference only.)

Formula: volume (m³) × density (kg/m³) = weight (kg). Price = weight × price per kg. Results are estimates only.

Result

* Contact us for official quotations with up‑to‑date material costs and logistics.

Gallery / Examples

Add your factory photos, packaging samples, and construction cases here.

Frequently Asked Questions

Do you provide installation services?

We focus on production and delivery only. If needed, we can refer third‑party installers.

What thickness and density can I choose?

EPS density ranges 7–20 kg/m³. XPS thickness is commonly 3, 4, 5 cm. We can cut to your required sizes.

How fast can you deliver?

Typical lead time is 3–7 days depending on order size and current queue. Contact us for an exact schedule.

Can you make custom packaging shapes?

Yes. Send drawings or samples. We provide sample proofing before mass production.

What is the minimum order quantity?

No minimum order for standard products. Custom shapes may require minimum quantities - contact us for details.

Do you offer samples before production?

Yes, we provide samples for custom orders. Small samples are usually free, larger samples may have a nominal charge.

What payment methods do you accept?

We accept bank transfers, cash on delivery, and other local payment methods. Payment terms can be discussed based on order size.

Can you deliver outside Phnom Penh?

Yes, we deliver nationwide across Cambodia. Delivery costs vary by location and order size.

What is the shelf life of your products?

EPS and XPS products have excellent durability when stored properly. Dry mortar products have a 12-month shelf life when kept dry.

Do you provide technical support?

Yes, our technical team can provide guidance on product selection, application methods, and troubleshooting for construction projects.